Service Hotline:

For everyone to explain the characteristics of the slitting machine and debugging matters needing attention

Release time:

2022-04-08 14:17

Source:

1. Slitting Machine Features

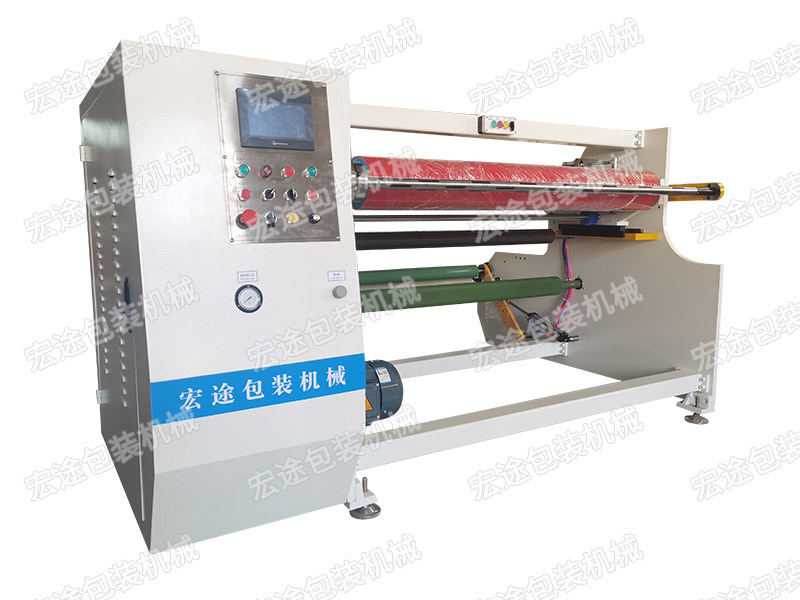

Slitting Machine is a mechanical equipment that cuts wide paper or film into several narrow strips. It is often used in papermaking machinery and printing and packaging machinery. The following are the characteristics of the slitting machine we sorted out for you:

1. The thick steel plate is firmly welded and the angle is balanced, so that the machine can work stably at high speed.

2. The whole machine adopts chrome-plated steel pipes, each of which is dynamically balanced.

3. Unwinding adopts a 3-inch inflatable unwinding reel with a maximum unwinding diameter of 600mm, equipped with a magnetic powder tension controller and an automatic side-to-side device.

4. The winding adopts a 3-inch inflatable drum and a magnetic powder tension controller, which is simple to cut, and the limit large winding diameter can reach 600mm; beautiful and neat winding

5. The cutting knife can be an industrial surgical blade or Flat blade (art blade), and adjustable knife between 18mm and 1600mm.

6. The main shaft and the round knife adopt a continuously variable speed system, which can be used as high and low speed adjustment and forward and reverse switching control; the electronic speed control system manually adjusts the machine speed, which is convenient and simple.

7. Equipped with double-sided diamond grinding and sharpening system, the service life of the grinding wheel can reach two years; do not disassemble the sharpening knife, keep the blade sharp for a long time; achieve good cutting quality; have dust absorption ability, keep the cloth and track clean.

8. The imported precision ball screw and slide rail are used to advance the cutting width in parallel. The imported AC motor adjustment system can steplessly adjust and control the cutting speed to achieve high-precision cutting, and the accuracy can be controlled within 0.1mm.

9. Equipped with high-precision correction device system to further ensure cutting accuracy.

10. Chinese and English operation interface, LCD screen, can directly input a variety of load cutting width and quantity settings, and is equipped with manual/automatic conversion function, the operation is simpler and more convenient.

11. Adopting fast feeding design, feeding and blanking can be completed with only one action, which effectively reduces the labor in production and improves production efficiency.

12, automatic counting device, at a glance.

2. debugging slitting machine What matters should be paid attention to?

1. Slitting machine debugging Operators are familiar with the operation process, operate strictly according to the operation process, and hold the qualification certificate. This also includes that the operator must not have long hair, wear gloves to operate the machine, and fasten the cuffs with clothes (except for loading and unloading knives). This is to ensure the safety of the operator when operating the slitting machine.

2. After the connection of the entire production line in the slitting machine is correct, power on the slitting machine. After powering on, it is not allowed to open the electric control door at will. The operator should pay attention to touching the electrical documents with his hands when operating the metal slitting machine to prevent electric shock.

3. The slitting machine is not allowed to hit the control door at will, and the slitting machine is not allowed to touch the transmission part with body, hand or head. Do not bring the head too close to the material and the roller when visually checking the operation. Do not lean against any part of the machine; at the same time, do not touch the roller with your hands during the operation of the slitting machine;

4. Pay attention to the coordination of strength and the fixed feeding position when using the slitting machine to feed the material. Prevent the raw material from falling and hurting your feet. At the same time, ensure that the position of the material on the uncoiler is accurate.

5. Pay attention to the pulley of the discharge arm when blanking to prevent the discharge arm and winding shaft from falling off and hurting their feet.

More information